In the fast-paced world of culinary arts, where every second counts and the margin for error is razor-thin, the importance of a well-structured kitchen workflow cannot be overstated. Effective kitchen workflow planning serves as the backbone of any successful culinary operation, ensuring that tasks are executed seamlessly and resources are utilized to their fullest potential. From bustling restaurants to intimate catering services, a meticulously organized kitchen enables chefs and staff to navigate the complexities of food preparation with precision and speed. This article explores the pivotal role of kitchen workflow planning in maximizing efficiency, highlighting key strategies and best practices that can transform chaotic culinary environments into models of productivity. By understanding and implementing these principles, kitchen professionals can not only enhance their operational performance but also elevate the overall dining experience for their patrons.

Table of Contents

- Understanding Kitchen Workflow Dynamics for Improved Operations

- Assessing Common Bottlenecks in Kitchen Processes and Solutions

- Implementing Strategic Layout Designs to Enhance Productivity

- Measuring Success: Key Performance Indicators for Kitchen Workflow Efficiency

- Future Outlook

Understanding Kitchen Workflow Dynamics for Improved Operations

Effective kitchen workflow dynamics hinge on a carefully orchestrated series of tasks that maximize productivity while minimizing chaos. At the core of this process are several key elements that contribute to a seamless operation. Station design is critical; ensuring that each area—prep, cooking, plating, and cleaning—flows intuitively helps reduce unnecessary movement and saves time. Considerations such as equipment placement and ingredient accessibility also play pivotal roles in streamlining activities. Moreover, proper task allocation ensures that each team member knows their responsibilities, which enhances teamwork and reduces overlaps in duties.

Furthermore, the implementation of technology can significantly enhance kitchen workflow. Utilizing tools like digital order screens and inventory management software can lead to better coordination among kitchen staff and front-of-house operations. Regularly analyzing workflow through techniques such as time-motion studies can reveal bottlenecks and inefficiencies, providing insight into necessary adjustments. Keeping communication open and utilizing feedback from staff allows for continuous improvement, creating an adaptive environment that supports peak performance. Below is a simplified view of how different elements contribute to workflow efficiency:

| Element | Impact on Workflow |

|---|---|

| Station Design | Streamlines processes, reduces movement |

| Equipment Placement | Enhances accessibility, saves time |

| Task Allocation | Improves team efficiency and clarity |

| Technology Use | Facilitates real-time communication and management |

| Feedback Mechanism | Encourages continuous improvement |

Assessing Common Bottlenecks in Kitchen Processes and Solutions

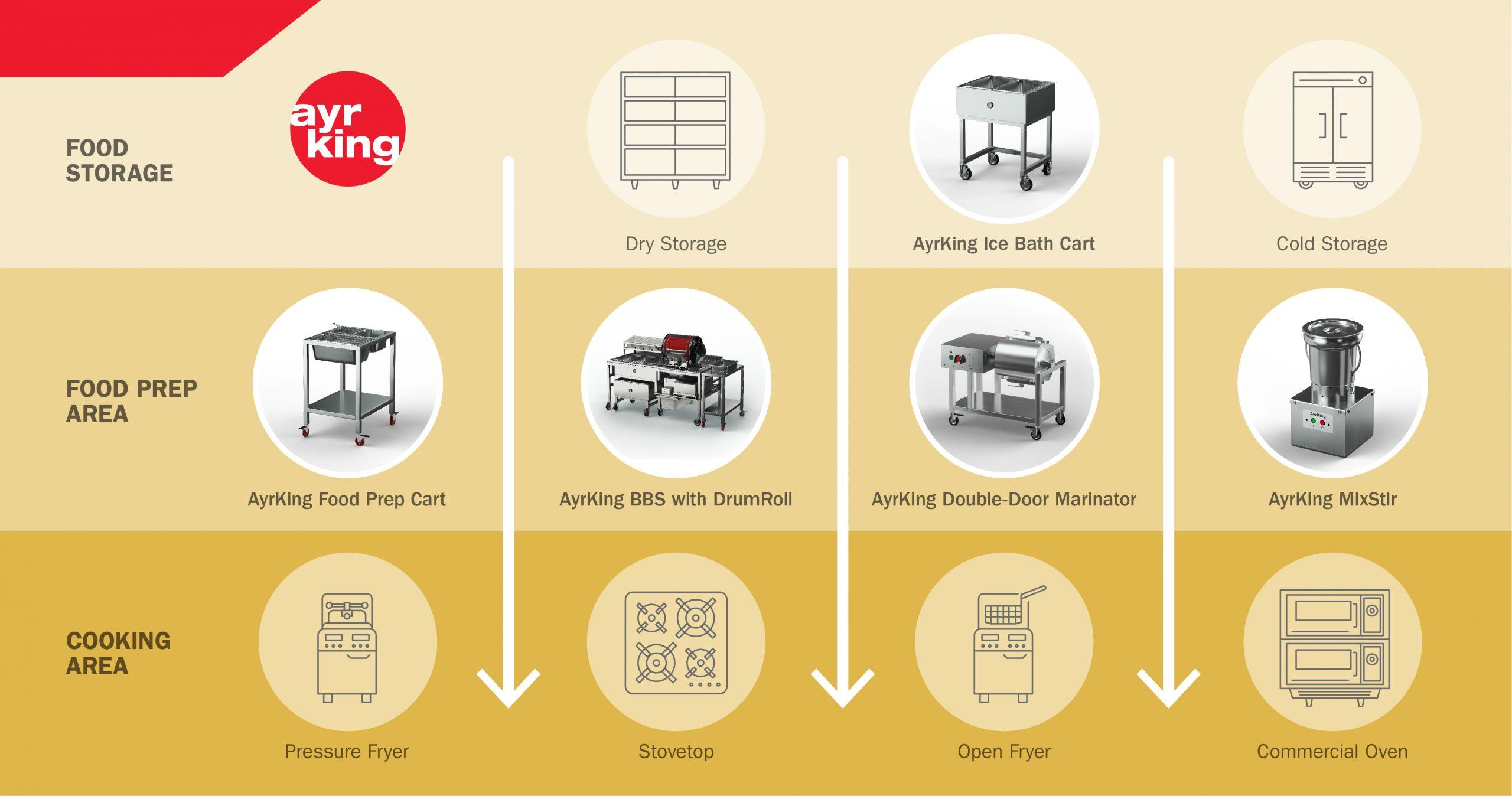

In any kitchen operation, identifying and addressing bottlenecks is crucial for maintaining a smooth workflow. Common culprits include inefficient layout, poor communication among staff, and inadequate equipment. An unorganized workspace can lead to delays, as staff may spend too much time looking for tools or ingredients. Additionally, when there’s a lack of clear communication, tasks may overlap or fall through the cracks, further hampering productivity. By evaluating the kitchen’s current layout and workflow, managers can pinpoint these issues and make adjustments.

Implementing solutions involves both physical and procedural changes. Consider the following strategies to alleviate bottlenecks:

- Redesign the workflow: Arrange stations to minimize movement and keep frequently used items within reach.

- Standardize communication: Utilize kitchen display systems or shift briefs to ensure everyone is on the same page.

- Invest in equipment: Upgrade or add tools that can expedite processes, like high-quality knives or commercial-grade ovens.

| Bottleneck Issue | Proposed Solution |

|---|---|

| Poor station layout | Reorganize workspace |

| Overlapping tasks | Implement clear roles and responsibilities |

| Slow equipment | Upgrade tools and machinery |

| Lack of staff training | Conduct regular training sessions |

Implementing Strategic Layout Designs to Enhance Productivity

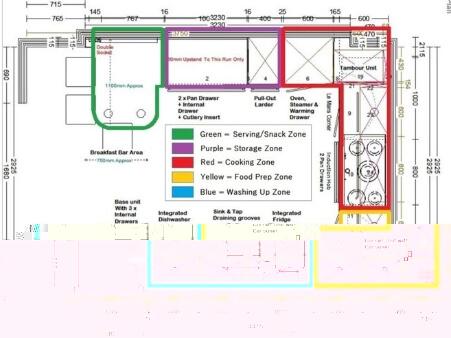

Creating an efficient kitchen layout is essential for streamlining operations and boosting productivity. Start by identifying the work zones within your kitchen, each tailored to specific tasks such as preparation, cooking, plating, and cleaning. Effective zoning minimizes unnecessary movement, allowing chefs and staff to flow seamlessly from one task to another. For instance, placing the prep area close to the cooking station can save valuable time during busy service hours. Additionally, consider implementing an open concept for easier communication among staff, and use visual cues to define each work zone, enhancing overall functionality.

Utilizing the right equipment and tools in designated areas can further increase efficiency. Invest in ergonomically designed workstations that cater to the needs of your staff, reducing fatigue and promoting well-being. To illustrate how various layout options can impact kitchen productivity, refer to the table below:

| Layout Type | Efficiency Benefit |

|---|---|

| Island Layout | Enhances movement and communication |

| G-shape Layout | Maximizes storage and workspace |

| L-shape Layout | Encourages a smooth workflow |

| Galley Layout | Reduces space for unnecessary movement |

by strategically considering the layout designs and how they influence traffic flow, your kitchen can achieve remarkable enhancements in productivity. Regularly revisiting your layout and incorporating feedback from staff will help maintain efficiency as your operations evolve.

Measuring Success: Key Performance Indicators for Kitchen Workflow Efficiency

To truly enhance kitchen workflow efficiency, establishing a framework of Key Performance Indicators (KPIs) is essential. These metrics not only help track progress, but also identify areas needing improvement. A few critical KPIs to consider include:

- Order Fulfillment Time: Measuring the time from order placement to delivery ensures responsiveness.

- Food Waste Percentage: Monitoring waste can highlight inefficient processes and ingredient overuse.

- Labor Productivity: Evaluating output per staff member guides staffing decisions and task allocations.

In addition to these, regularly analyzing kitchen throughput provides insight into how smoothly operations run during peak hours. For instance, keeping track of the number of orders processed per hour can serve as a benchmark for staff performance. A simple table can illustrate these metrics effectively:

| Metric | Current Value | Target Value |

|---|---|---|

| Order Fulfillment Time | 12 minutes | 10 minutes |

| Food Waste Percentage | 15% | 5% |

| Labor Productivity | 10 orders/hour | 15 orders/hour |

Future Outlook

effective kitchen workflow planning serves as the backbone of any successful culinary operation. By meticulously analyzing each step of the food preparation process—from ingredient sourcing to plating—restaurant owners and chefs can significantly enhance their productivity, reduce waste, and improve overall service quality. The implementation of organized workstations, strategic time management, and streamlined communication channels not only fosters a harmonious working environment but also elevates the dining experience for customers. As the culinary landscape continues to evolve, embracing these principles of efficiency will be paramount for establishments aiming to remain competitive. Ultimately, a well-structured kitchen workflow is not merely an operational necessity; it is a vital ingredient in the recipe for success that allows culinary professionals to focus on their true passion—creating exquisite dishes that delight and inspire.